How PIR Fresnel Lens Working For Induction Probes

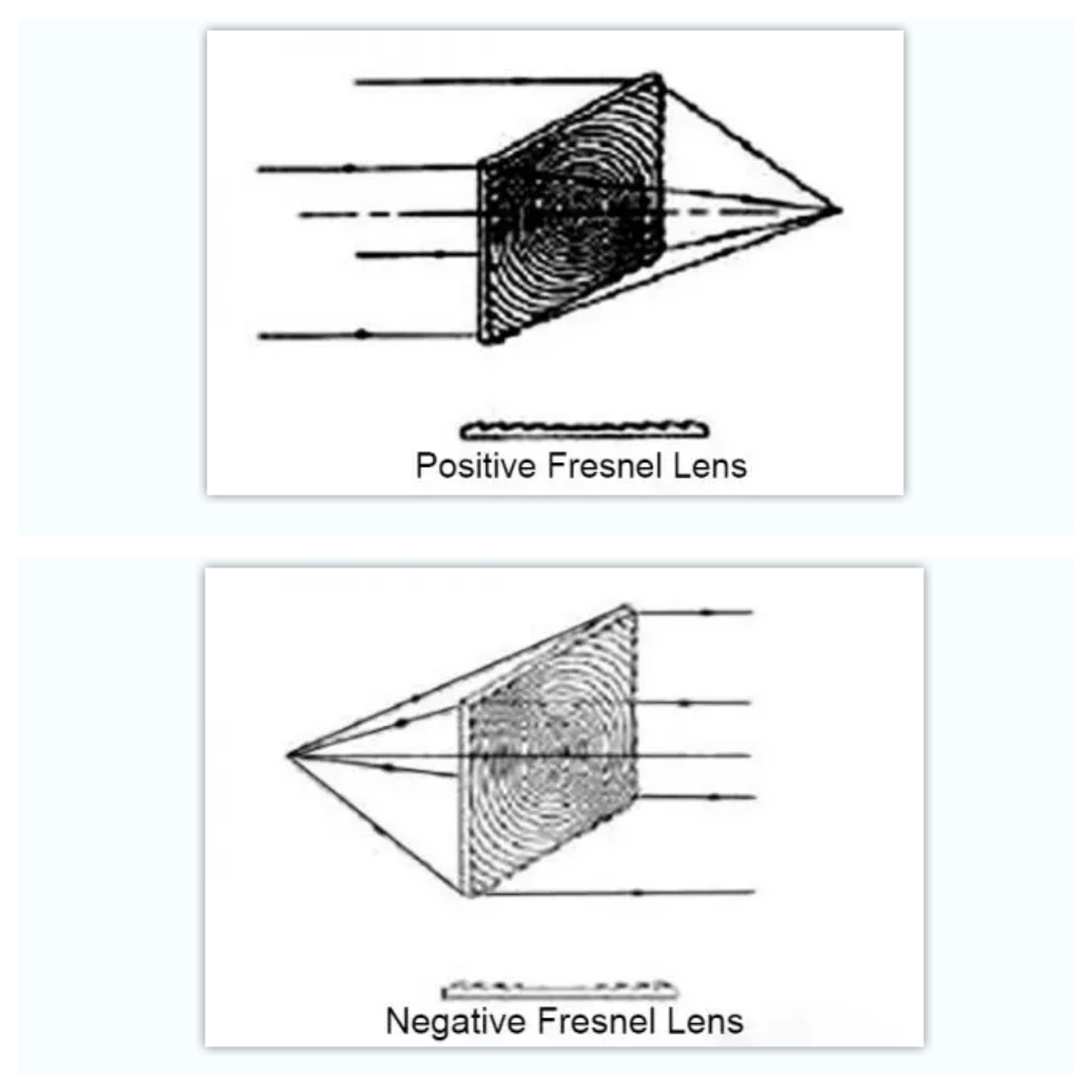

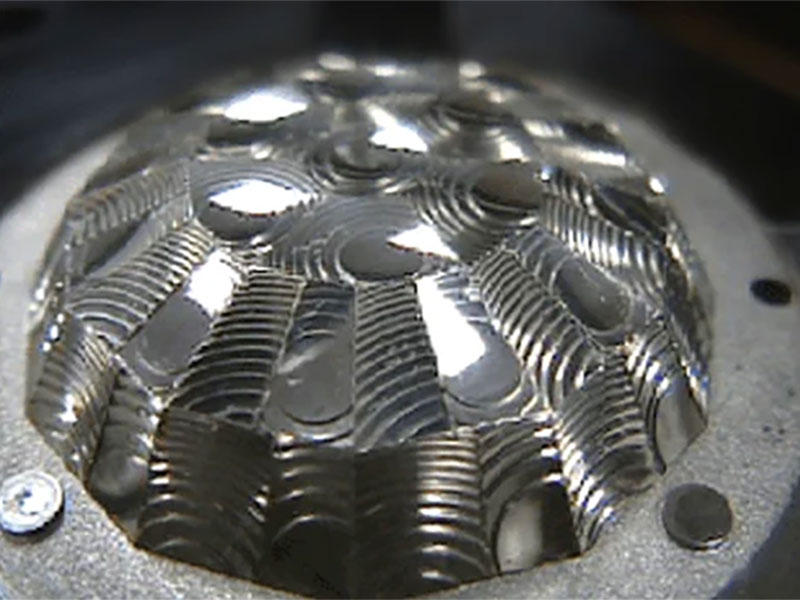

The Fresnel lens is a sheet, round or other shape that is injected or molded from polyolefin materials. There are two main functions of the Fresnel lens acting on the probe: one is focusing, which is to refract (reflect) the pyro-infrared signal on the PIR, and the second is to divide the detection area into several bright and dark areas. Zone, so that the moving objects entering the detection area can produce a changing pyro-infrared signal on the PIR in the form of temperature changes. Simply put, there are equidistant tooth patterns on one side of the lens. Through these tooth patterns, the optical bandpass (reflection or refraction) of the specified spectral range can be achieved. The bandpass optical filter of traditional polished optical equipment The cost is expensive. Fresnel lenses can greatly reduce costs. A typical example is PIR (Passive Infrared Detector). PIR is widely used in alarms. If you take one and take a look, you will find that there is a small plastic cap on each PIR. This is the Fresnel lens. The inside of the little hat is carved with teeth. This Fresnel lens can limit the frequency peak of incident light to about 10 microns (the peak of infrared radiation from the human body). The cost is quite low.

The Fresnel lens can focus the light passing through the narrow-band interference filter on the photosensitive surface of the silicon photoelectric secondary detector. The Fresnel lens is made of plexiglass and cannot be wiped with any organic solution (such as alcohol, etc.). When removing dust, rinse with distilled water or ordinary clean water first, and then wipe with absorbent cotton.

Structure Of PIR Fresnel Lenses Of Infrared Probes As “Eye Glasses”

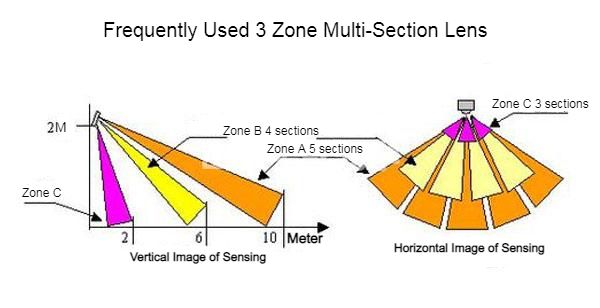

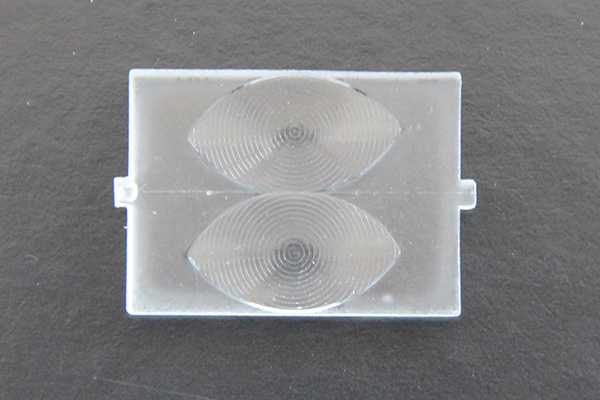

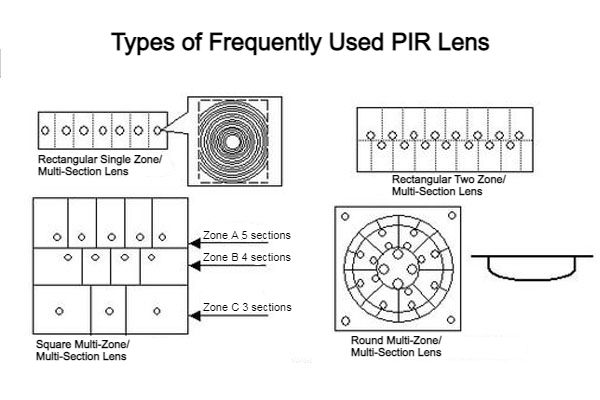

Fresnel lenses are the “eye glasses” of infrared probes. They are like human eye glasses. The proper use of them will directly affect the effectiveness of the use. Improper use will cause misoperation and leakage, which will cause users or developers to lose confidence in them. . Properly used to give full play to the role of human body induction, so that its application areas continue to expand. E-Tay Industrial can customize the infrared lens according to customer requirements, and usually take samples within 30 days. Fresnel lens has many ring lines and dense sensing angle and long focal length; the deep sensing distance of ring line engraving is long and focal length is short. The more the infrared light enters the concentric ring, the more concentrated and stronger the light is. Several concentric rings in the same row form a vertical induction zone, and the concentric rings form a horizontal induction section. The more vertical sensing areas, the greater the vertical sensing angle; the longer the lens, the greater the sensing section, the greater the horizontal sensing angle. If the number of sections is large, the movement range of the sensed human body will be small, while the number of sections are small, the moving range of the sensed human body will be larger. The concentric circles of different zones are interlaced with each other to reduce blind areas between zones. Blind areas are formed between zones, between sections, and between sections. Because the lens is restricted by the angle of the infrared probe’s field of view, the vertical and horizontal sensing angles are limited, and the lens area is also limited. Lenses are classified into: long, square, and round in appearance, and classified into single-zone and multi-segment, dual-zone and multi-segment, and multi-zone and multi-segment in terms of function.